Spark spectrometer Belec Vario Lab

Flexibility and Accuracy combined

The Belec VARIO Lab is a stationary spark spectrometer that enables precise and versatile analyses in the laboratory or in production.

Reliable.Quality.Control

The Belec Vario Lab impresses in metal analysis with its maximum flexibility in analyzing a wide variety of sample sizes and shapes. A sparking probe is optionally available for even more versatile applications.

Your benefits at a glance

- Ergonomic set-up

for comfortable working at an optimal height. - Practical drawer

All accessories fit into the integrated drawer. - User-friendly

Preset and easily selectable operator functions. - Maximum flexibility

for all kinds of sample sizes and shapes - Small size and weight

Fits through standard doors. - Open sparking stand design

Access from three sides for huge and bulky samples. - Multi-base capable

for different alloys. - Reduced analysis cycles and minimal argon consumption.

- Optional sparking probe for flexible applications.

To Inquiry

Maximum flexibility in spectral analysis

Your testing options for versatile applications

The Belec Vario Lab offers you maximum flexibility: The stationary spark spectrometer can optionally be equipped with a sparking probe. Choose the right probe for your requirements from three high-quality probes:

- UV+ Probe – for the highest precision in sensitive analyses

- Argon Probe – versatile and reliable

- Air Probe – ideal for quick mix-up tests without argon consumption

This selection allows you to optimally adapt the Belec Vario Lab to your specific applications.

| Sparking Probe Features | UV+ Probe (N*) | Argon Probe | Air Probe |

| argon-flushed sparking probe incl. C-analysis | YES | YES | - |

| argon-flushed sparking probe incl. P, S, N*-analysis | YES | - | - |

| probe connector system | YES | YES | YES |

| quick mix-up checking | - | - | YES |

| multi fibre quartz optics, 3m to 8 m* | YES | YES | YES |

| adapters for tubes, wires + small parts | YES | YES | YES |

| non-destructive material testing | YES | YES | YES |

*optional

| Features | Details |

| Weight analysis unit | 176.6 lbs. (80 kg) |

| Width | 26.8 in. (680 mm) (additional 2.4 in. (60 mm) on optional probe plug) |

| Height | 44.7 in. (1135 mm) |

| Depth | 37.2 in. (945 mm) |

| Software | Belec WIN 21 |

| Analysis spectrum | All common metals |

Discover all the technical details of the Belec Vario Lab in our product brochure.

Belec Vario Lab - Universally Applicable with additional Probe

The Belec Vario Lab is one of the most powerful spectrometers of its kind. The fields of application are not limited. Whether in the laboratory or workshop – there is hardly any location that cannot be considered.

An additional Sparking Probe can further enhance the functionality of the instrument. For the analysis of big, bulky or indestructible samples, you can use one of our sparking probes. With this unique option, the Belec Vario Lab covers all possible applications for metal analysis.

Interested?

Contact your local representative

With its over 40 international representations, Belec is present all over the world and can therefore grant fast and secure service. As a manufacturer of optical emission spectrometers, we ensure that our solutions are available worldwide and that you are always optimally supported.

Product features

Laboratory Spectrometer Belec Vario Lab

Discover the features of the Belec Vario Lab and download the full brochure. Learn all about the features and benefits of this powerful stationary spark spectrometer.

Accessories of Belec Vario Lab

Belec offers a comprehensive range of accessories for the stationary spark spectrometer Belec Vario Lab. With tailor-made solutions for spectral analysis, you can increase the efficiency and precision of your applications.

Perfect adaptation for every sample

Our specially developed adapters and accessories enable you to precisely analyze even challenging samples such as wires, pipes or small parts. In addition, individually customizable options are available to you that make your everyday work easier and improve the quality of your results even further.

UV+ Probe

UV+ Probe

Argon Probe

Argon Probe

Air Probe

Air Probe

![[Translate to Englisch:]](/fileadmin/_processed_/0/e/csm_Drahtadapter_Vario_fbc136192d.jpg) Wire Adapter

Wire Adapter

![[Translate to Englisch:]](/fileadmin/_processed_/d/8/csm_Rohradapter_Vario_99563ab8f3.jpg) Tube Adapter

Tube Adapter

disk grinding machine

disk grinding machine

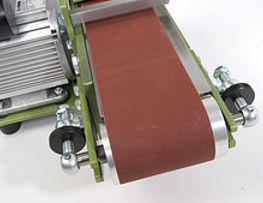

belt grinding machine

belt grinding machine

angle grinder

angle grinder