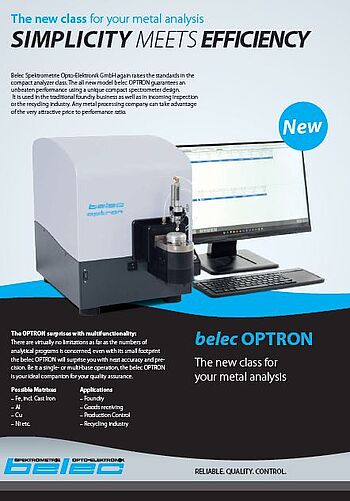

Belec OPTRON - Precision in a new dimension

Your metal analyzer for accurate analyses

Our Belec OPTRON combines state-of-the-art technology with proven quality. Ideal for stationary applications, it delivers reliable and fast results – perfectly tailored to your needs.

SIMPLICITY MEETS EFFICIENCY

Belec has again raised the standards in the compact analyzer class. Our Belec OPTRON impresses with its innovative spectrometer design and sets new standards in performance and precision. Whether for melt control in foundries, at goods receiving, in recycling or in regular quality assurance - this spectrometer impresses at every application.

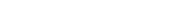

Your benefits at a glance

- Excellent precision

Thanks to the latest technology, even with the smallest alloy differences. - Compact design

Small footprint and weight - Near Maintenance free operation

Minimal effort for maximum operating time. - Multi-Matrix capable

Flexible for the analysis of a wide variety of metal alloys. - Complete analysis in just 10 seconds

- Very cost effective

| Features | Details |

| Weight analysis unit | 23 kg |

| Width | 330 mm |

| Height | 435 mm |

| Depth | 580 mm |

| Analysis spectrum | Fe incl. Cast Iron, Al, Cu, Ni etc. |

Discover all the technical details of the Belec OPTRON in our product brochure.

- Foundries

- Goods Receiving

- Recyclingindustry

- Production Control

Our Belec OPTRON delivers accurate results in the shortest possible time, ensuring efficient processes and the highest quality standards. Reliable analyses guarantee that delivered metals and alloys meet the required specifications - for maximum safety in incoming goods.

To Inquiry

Interested?

Contact your local representative

With its over 40 international representations, Belec is present all over the world and can therefore grant fast and secure service. As a manufacturer of optical emission spectrometers, we ensure that our solutions are available worldwide and that you are always optimally supported.

Product Highlights

Metal analyzer Belec OPTRON

The new class for your metal analysis

Discover the features of the Belec OPTRON and download the full brochure. Learn all about the features and benefits of this powerful stationary spark spectrometer.

Accessories for Belec OPTRON

For optimal results, Belec offers an extensive range of accessories for the stationary spectrometer Belec OPTRON. With tailor-made solutions for metal analysis, you increase the flexibility and efficiency of your analyses.

Flexible solutions for every application

Our specially developed adapters and accessories enable you to quickly and precisely analyze even challenging samples such as wires, pipes or small parts. In addition, we offer individually adaptable solutions that make your work easier and further optimize the analysis results.

Wire Adapters

Accurate analysis of wires of different sizes

With the wire adapter from Belec you can precisely analyze even wires with a diameter of Ø 2 mm to Ø 12 mm. The holder for wire adapters is simply plugged onto the head of the standard argon probe so that the adapters are securely attached and the analysis of wires is easy.

Your advantages:

- Wire adapter set for wires from Ø 2 mm to Ø 12 mm with spacing of 0.5 mm

- Additional adapters for particularly thin wires from Ø 0.5 mm to Ø 2 mm

- Adapter is securely attached by the holder to ensure an optimal connection to the probe head

This wire adapter is the perfect solution for the accurate analysis of a wide range of wire diameters, even with very thin wires.

Optimize your metal analyses - with the wire adapter from Belec for fast and precise results!

Tube adapter

Accurate analysis for all pipe diameters

For your specific applications, we offer a complete tube adapter set for standardized pipe outer diameters. With this set, you can easily analyze tubes of different sizes - ideal for all your on-site metal analyses.

Flexible and portable:

- 9-piece tube adapter set for common pipe diameters

- Compact case for easy transport and storage

- Easy handling – ideal for use on the trolley

- Tube adapters for large and small diameters – for maximum versatility

If you require special dimensions, we can also manufacture tube adapters to special sizes or individual pieces on request.

Contact Us

for individual adapter solutions.

![[Translate to Englisch:] Metallanalysator Belec OPTRON [Translate to Englisch:] Metallanalysator Belec OPTRON](/fileadmin/_processed_/d/5/csm_Giesserei_Optron_AdobeStock_161136017_06228af220.png)